Contributed by Bruce Rosen

Bay Simulations, Inc.

![45.1.1]()

The America’s Cup is the world’s oldest sporting trophy. Big, technology-laden racing yachts representing yacht clubs from countries around the world compete for the right to hold and defend this ornate piece of silver.

Since 1992, the “IACC rule” has governed the size and other general characteristics of the roughly 70-foot yachts. Now a proposed 90-foot rule would give the naval architects more opportunities to explore a new design space, developing hull and appendage shapes intended to give their teams an edge over the competition.

“Gridgen and Tecplot give us the confidence that we will be able to effectively communicate and collaborate with America’s Cup teams and yacht designers all over the world.” – Bruce Rosen, South Bay Simulations, Inc.

With recent syndicate budgets running in excess of $100 million, teams invest significant effort in testing their hydrodynamic designs. Every angle is investigated with a wide range of tools from simple empirical relationships to very expensive scale model towing tank tests.

Designers also use an arsenal of advanced software to perform extremely sophisticated numerical calculations aimed at solving the fully 3D and viscous Navier-Stokes equations that govern the fluid dynamic flow fields under the water and in the air.

SPLASH Software Helps Designers Understand Flow Dynamics

One popular tool for predicting yacht performance is the SPLASH free-surface flow software, developed by Bruce Rosen, president of South Bay Simulations, Inc. SPLASH is a panel code, a computerized method for solving the 3D inviscid fluid flow equations governing the underwater portion of the flow.

SPLASH was originally developed to support skipper Dennis Conner’s successful 1987 campaign to win back the America’s Cup from Australia, who had just ended the New York Yacht Club’s 150-year monopoly of the trophy. Since then, SPLASH has undergone continuous refinement, and has been used by about one-half of the many competing syndicates.

In SPLASH, fluid source and/or doublet singularities of unknown strength are distributed across each panel of the model. Boundary conditions are applied at panel control points, yielding a set of linear equations to solve for the strengths of the sources and doublets. This makes it possible to compute the corresponding flow field and performance-determining drag, side forces, and rolling and yawing moments that act on the yacht as it moves through the water.

Panel codes are often not considered to be true Computational Fluid Dynamics (CFD), due in large part to the greatly simplifying inviscid flow assumption. But, for a yacht moving through the water, the additional physical and numerical aspects due to the free-surface waves at the air/water interface can be just as complicated, and difficult to capture, as other types of phenomena normally pursued using viscous CFD codes.

Unraveling the Complexities of Yacht Design

As seen in Figures 1 and 2, the wave shape, the waterline contour, and the extent of the wetted portion of the hull are not known in advance of the flow simulations and must be determined as part of the flow calculations. This requires special hydrostatic and hydrodynamic boundary conditions on the free-surface panels.

![45_1_2]()

Figure 1: Hull bottom: The distribution of grid angles along the waterline is highly unusual and difficult to generate using standard methods. Other enhanced capabilities include adjusting the usual first spacing at the boundary, as the mesh is being generated, to maintain a desired first spacing normal to the boundary.

These boundary conditions are nonlinear, and they incorporate additional radiation conditions to ensure that waves propagate only downstream and not upstream. As a result, the free-surface panel boundary conditions are considerably more complicated than the standard ones used on solid surface panels such as for the hull and appendages.

The dynamic sink and trim (pitch angle) of the model “underway” are also not known in advance. A series of alternating SPLASH flow calculations and model re-flotations and re-panelizations are conducted, ultimately converging to final solutions. For yachts, the entire process can be automated within ACCPAN software, a companion product to SPLASH.

![45_1_3]()

Figure 2: Model details allow for capturing free-surface waves at nonzero heel angles while including the effects of an immersed transom and the lifting surfaces (keel and rudder) and their trailing vortex sheet wakes.

ACCPAN constructs the SPLASH panel models using structured surface meshes distributed over the various yacht components, and over a portion of the free surface in the near vicinity of the yacht. ACCPAN automatically generates the panelizations based on designer-supplied yacht surface geometry databases, and other model and test condition inputs. This generation uses the elliptic grid algorithms available in Gridgen, CFD meshing software from Pointwise, Inc.

When setting up the simulations, the main objective is to distribute a sufficient number of panels over the yacht and free surface to adequately resolve all significant aspects of the flow. This is difficult to accomplish, yet quality of the panelization is critical.

“These concepts and approaches are very consistent with one another and, taken together, help to compensate for most if not all of the other accompanying complexities and difficulties.” – Bruce Rosen, South Bay Simulations, Inc.

The modeling of the lifting appendages and their trailing vortex sheets adds significantly to the overall complexity. It is difficult to achieve adequate panel density on the hull and free surface adjacent to the appendages. Even more important, at high heel angles, the overall quality of the hull and free-surface panelizations suffer greatly due to the attachment of the keel and rudder-trailing vortex wakes to the hull centerline, regardless of heel angle. An attendant bunching up of panels occurs to windward, and a stretching out of panels occurs to leeward.

Increasing the panel density alone does not always yield higher quality results. Computer memory and CPU execution time increase exponentially with the number of panels. While a single SPLASH panel model flow solution requires only about one CPU-minute to complete, an average of about eight such solutions must be repeated to capture all the nonlinear effects, and this must be carried out at each of 100 to 200 distinct test points.

To add to the complexity, designers’ tools must contend with highly asymmetric mesh boundaries, a waterline contour, and wetted surfaces that feature regions of very high curvature. These result somewhat randomly from the intersection between the yacht geometry and the yacht’s own steady wave system.

Gridgen Helps Designers Converge on Better Designs

Gridgen’s elliptic meshing algorithms provide the high-quality panelizations required to make it all work. ACCPAN also incorporates methods to externally specify parameters used within Gridgen to control elliptic mesh generation. “Millions of distinct ACCPAN panelizations and SPLASH flow calculations have been produced to date, in support of numerous America’s Cup design programs,” says Rosen.

The final SPLASH flow solution for this panel model (Figure 3) shows the distribution of pressure over the yacht surfaces and on the free surface where the wave elevation is proportional to the pressure coefficient.

![45_1_4]()

Figure 3: View of hull bottom. The final SPLASH flow solution for this panel model shows the distribution of pressure over the yacht surfaces and on the free surface (where the wave elevation is proportional to the pressure coefficient).

Rosen feels there are certain advantages in terms of reliability and accuracy using a low-order panel code, with structured meshes, strictly planar wake models, and panel pressure integration for forces and moments. “These concepts and approaches are very consistent with one another and, taken together, help to compensate for most if not all of the other accompanying complexities and difficulties,” says Rosen.

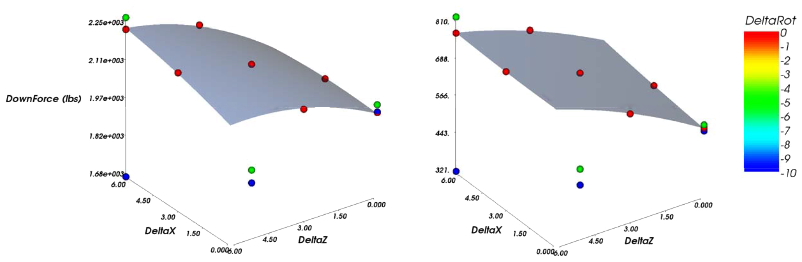

Results of numerical flow simulation test results are often evaluated by comparison with experimental towing tank data for a subscale model (Figures 4 and 5). Hydrodynamic characteristics of interest include the drag at non-lifting conditions (i.e., with yaw, tab and rudder set to zero), and the effective span (a single measure of side-force generating efficiency). These are functions of both the yacht’s forward speed and its heel angle. The figures illustrate typical absolute and relative (boat-to-boat) agreement between SPLASH calculations and experiment.

![45_1_5]()

Figure 4: Drag predictions at non-lifting conditions vs. tank data.

There are many other tasks where use of Gridgen is critical, says Rosen. These include:

- Interrogation of designer-supplied yacht surface geometry databases

- Modification and repair of database surfaces; visual inspection and troubleshooting of ACCPAN-generated models

- Research and development of new panelization strategies

- Customized panel model generation for non-standard yacht geometries or for non-yachting applications

Gridgen software also offers a complete suite of volume meshing tools for structured, unstructured, and hybrid meshes so it can be used when simulation needs call for other types of CFD simulation, such as full Navier-Stokes.

America’s Cup teams typically undertake numerical model tests for a very large number of similar but slightly different yacht designs. In these tests, the Gridgen scripting language, Glyph, can be used to automate as much of the database preprocessing as possible.

Tecplot Helps Designer Communicate with Racing Teams

Performing flow calculations is critical to the improvement of racing yacht designs. However, using software such as SPLASH and Gridgen can only get designers so far. Once simulation runs are completed, the designers must be able to view the results and communicate the significance thereof to others.

To view the results of their flow simulations, the analysts at South Bay Simulations use Tecplot scientific visualization software from Tecplot, Inc. “We work on Linux with command-line codes and shell scripts, which aren’t very graphical,” says Rosen, adding that his company uses Tecplot for all their presentation needs (including all the figures shown here).

Summing it all up, Rosen says that “Gridgen and Tecplot give us the confidence that we will be able to effectively communicate and collaborate with America’s Cup teams and yacht designers all over the world.”